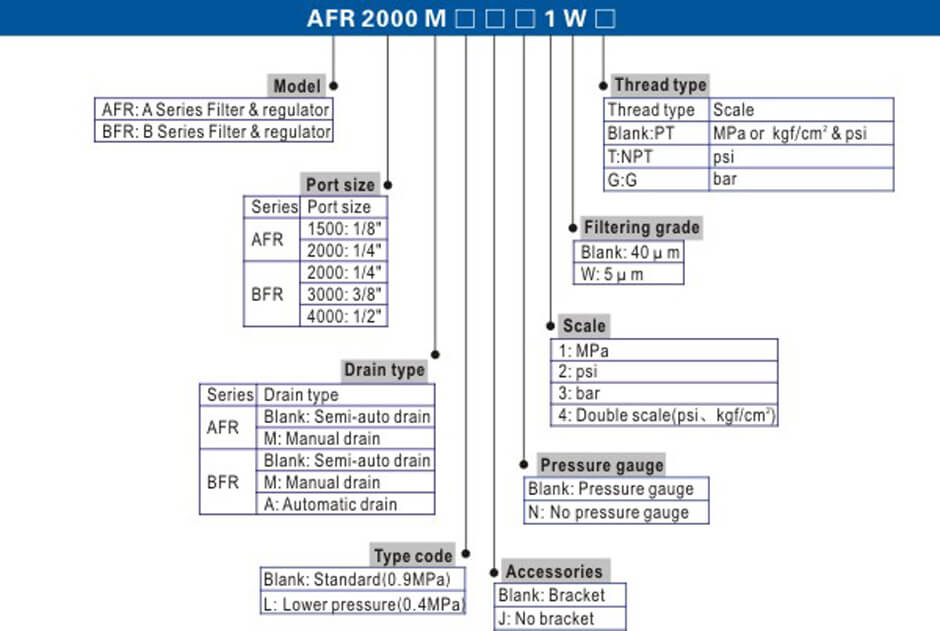

AIRTAC Type AFR,BFR Series Air Filter and Regulator

AFR2000,BFR2000,BFR3000,BFR4000

AIRTAC Type AFR,BFR Series Air Filter and Regulator

General Introduction

Filter and regulator together as one part, make it has compact dimension. Filter adopts novel vane design with high division efficiency and differential pressure discharge device. It can discharge water automatically. Regulator valve adopts balanced inlet structure with the advantages of stable pressure, high precision, and quick reaction.Help filter liquid and foreign particles from compressed air line, widely used for pneumatic tool and components.

Product Feature:

1.The structure is delicate and compact, which is convenient for installation and application.

2.The pressed-in self-locking mechanism can prevent the abnormal movement of the set pressure caused by external interfere.

3.The pressure loss is low and the efficiency of water separating is high.

4.In addition to standard type, lower pressure type is optional (The highest adjustable pressure is 0.4MPa).

Technical Specification

| Model: | AFR1500 | AFR2000 | BFR2000 | BFR3000 | BFR4000 | |||||

| Fluid: | Air | |||||||||

| Port Size: | PT1/8 | PT1/4 | PT1/4 | PT3/8 | PT1/2 | |||||

| Filtering Grade: | 40μm or 5μm | |||||||||

| Pressure Range: | Semi-auto and automatic drain:0.15~0.9MPa(20~130psi); Manual drain:0.05~0.9MPa(7~130psi) | |||||||||

| Max Pressure: | 1.0MPa(145psi) | |||||||||

| Proof Pressure: | 1.5MPa(215psi) | |||||||||

| Temperature Range: | -5~70℃ | |||||||||

| Capacity of Drain Bowl: | 15CC | 60CC | ||||||||

| Weight: | 260g | 400g | ||||||||

①PT thread, NPT thread and G thread are available.

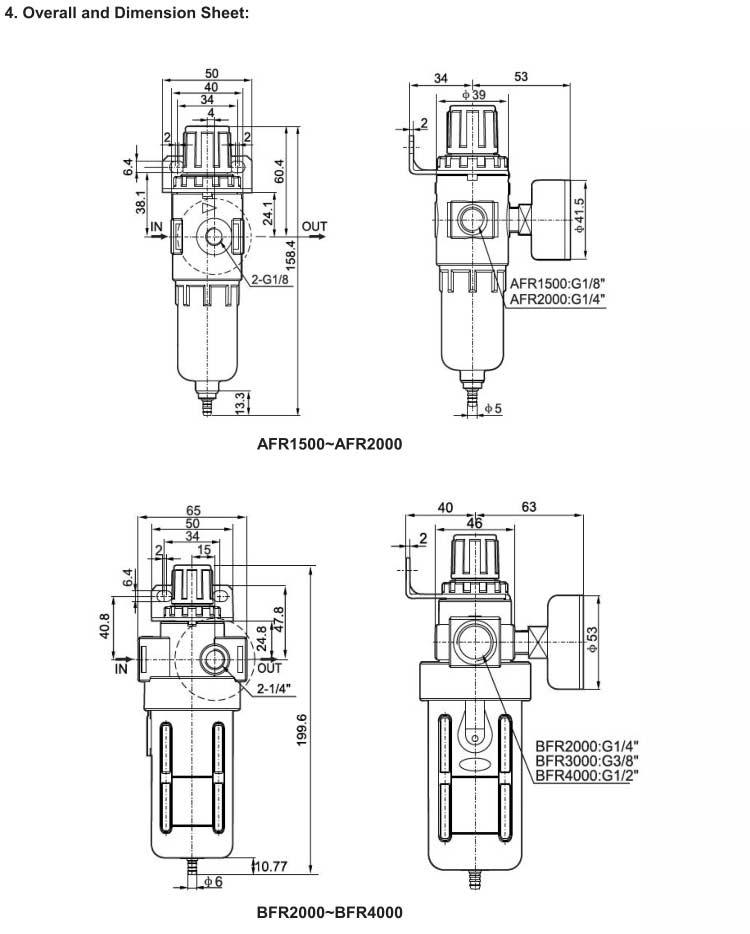

Outlook&Dimension

Installation & Usage:

1.Check whether the components have been damaged during transportation before installing and using.

2.Pay attention to whether the flow direction of air (notice “→” direction) and thread type are correct.

3.Please notice whether installation condition accords with technical requirements (such as “working pressure” and “applied temperature range”);

4.Avoid usage in an environment that exposes the filter and lubricator bowl through contact with Chlorine, solvent, aromatic essence, acid and alkali to avoid damage to the Filter and Lubricator bowl.

5.Regularly clean or change filter core. Lubricators and regulators shall be in descending order.

6.Keep the dust away. The dust cover shall be installed in intake and outlet when the device is dismantled and stored.

Product Details

Related products

-

Pneumatic Air Treatment

AIRTAC Type AFC,BFC Series FR.L Combination

-

Pneumatic Air Treatment

What Is SMC Type Series Filter Regulator And Lubricator

-

Pneumatic Air Treatment

AC1000~5000 Series Air Filter Combination (F.R.L Combination)

-

Pneumatic Air Treatment

Afr-2000 1/4 Pneumatic Filters