At Series Double Acting /Single Acting Pneumatic Actuator

with 2 optional: Double Acting and Single Acting(Spring Return).

1 million lifetimes and Max. torque is 4600Nm. CNC machine precision machining to reduce the size error of parts. ISO5211 mounting for ball valve and butterfly valve.

Actuator Type: Double Acting / Single Acting

Air Supply Pressure: 2 bar to 8 bar

Material: Aluminum alloy

Angle Of Rotation : 0° to 90°

Ambient Temperature: -40 to 160℃

Protection Class: IP65

Cup Color:sky blue orange grey

Introduction

WOLUN Series Double Acting Pneumatic Actuator rack and pinion designed to give long service life with light weight and high performance. Features include end of stroke adjustment, visual Indicator, namur interface and ISO mounting interface. Options include IP65 limit switch box with visual Indicator, Namur (direct mount) solenoid valves and a range of inserts to step the drive down.

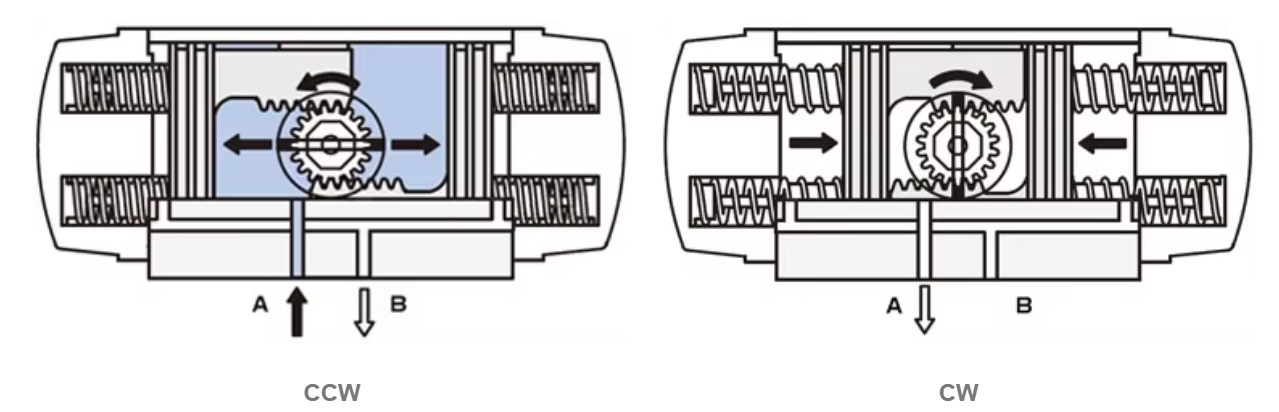

Working Principle of Single Acting (Spring Return) Pneumatic Actuator

CCW

Air to port A forces the pistons outwards, causing the springs to compress, The pinion turns counterclockwise while air is being exhausted from port B.

Loss of air pressure on port A, the stored energy in the springs forces the pistons inwards. The pinion turns clockwise while air is being exhausted from port A.

CW

Air to port B forces the pistons outwards, causing the springs to compress, The pinion turns counterclockwise while air is being exhausted from port B.

Loss of air pressure on port A, the stored energy in the springs forces the pistons inwards. The pinion turns clockwise while air is being exhausted from port A.

Benefits Of Spring Return Pneumatic Actuator

Supply air to open and air interrupted to close.Single-acting(Spring return) 90 degrees pneumatic rotary actuator.Spring-return pneumatic actuator provides you with automated fluid control solutions. Single-acting pneumatic actuators contain several springs. Its advantages include safety, explosion-proof, and auto return. ISO5211 mounting standard for ball valve and butterfly valve. Widely used for fluid control for shipyard, water treatment, food and beverage and so on. Use with positioner for easy industrial automation.

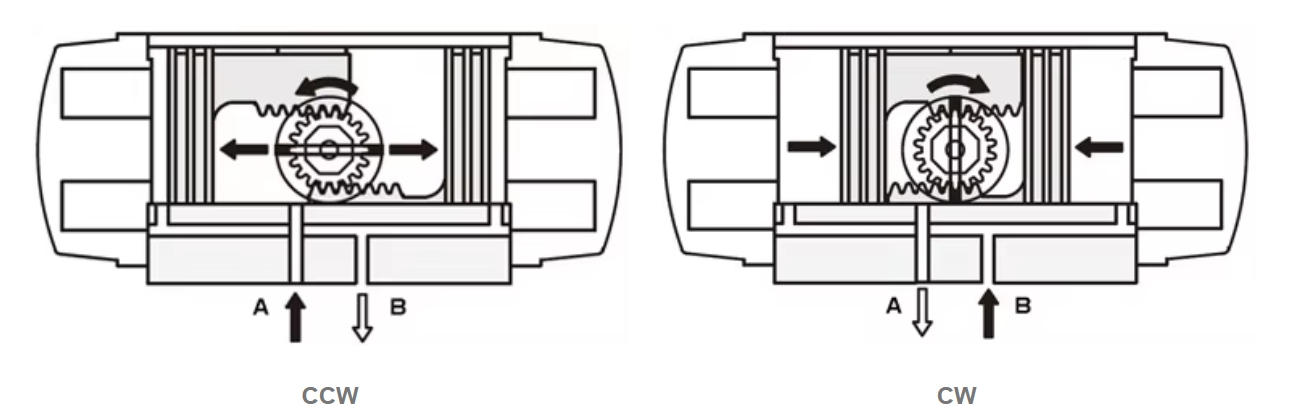

Working Principle of Double Acting Pneumatic Actuator

CCW

Air to Port B forces the pistons inwards, causing the pinion to turn clockwise while the air is being exhausted from Port A.

CW

Air to Port A forces the pistons outwards, causing the pinion to turn clockwise while the air is being exhausted from Port B.

Air to Port B forces the pistons inwards, causing the pinion to turn counterclockwise while the air is being exhausted from Port A.

Benefits Of Double Acting Pneumatic Valve Actuator

Supply air to open, supply air to closed. Responsive and high torque up to 4678Nm. Double-acting pneumatic rack and pinion actuator provides you with an automated fluid control solution. The advantages of double-acting pneumatic actuators include fast response, safety, and explosion protection. Suitable for opening or closing ball and butterfly valves. Widely used in water skid-mounted systems, food process skid-mounted systems, and so on. It can easily realize industrial automation when used with a positioner.

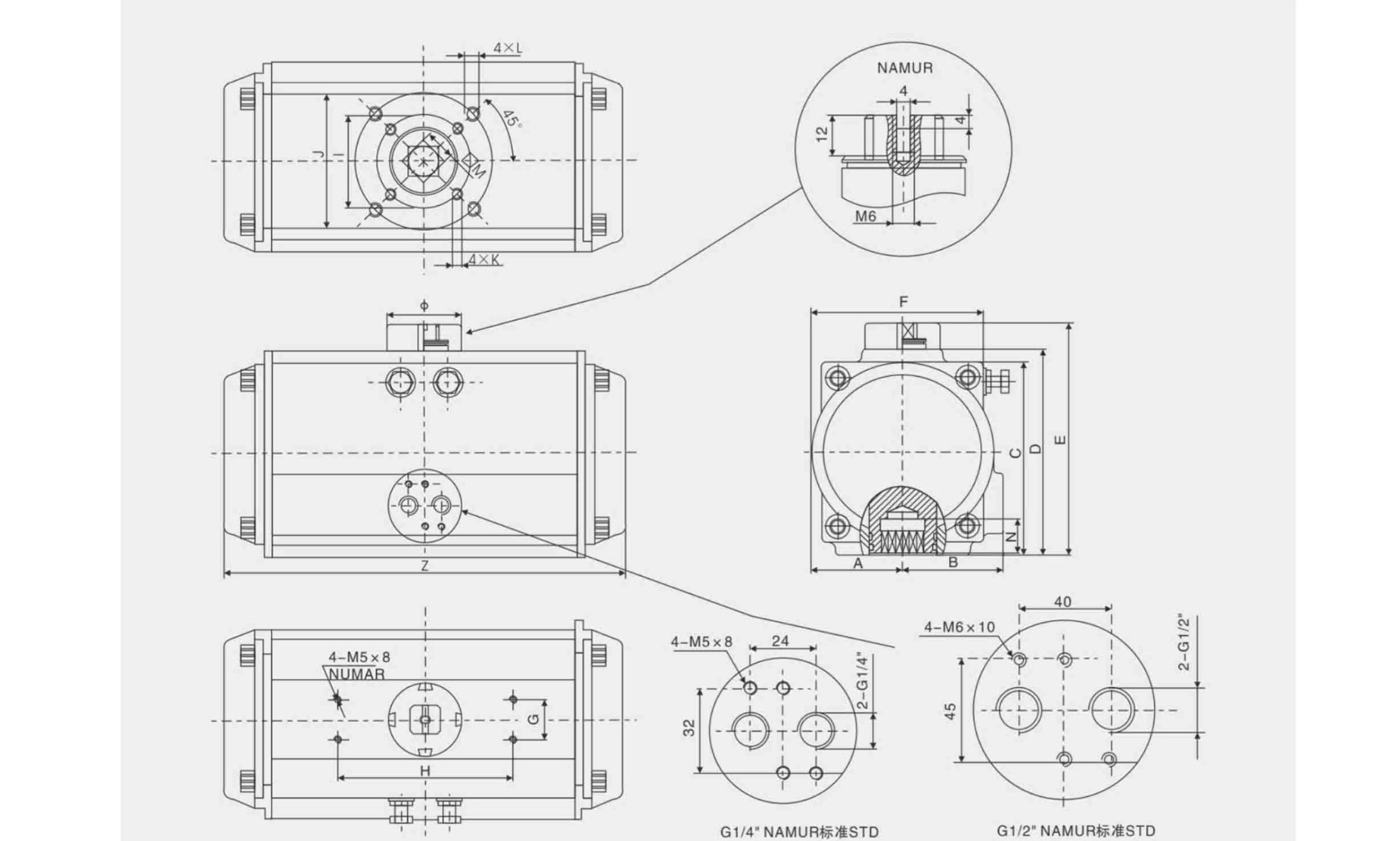

Interface Specification

1.Drive and Flange to lS05211 configuration for easy directmount onto a valve or connectionwith standardized mounting hardw are.

2.The NAMUR Drive Pinion and NAMUR top mounting connection for direct installation of accessories such as Limit Switch and Positioner.

3.Air supply connection is designed in accordance with NAMUR Standard to install solenoid valve.

Components,Materials & Corrosion-Proof of pneumatic actuator

| Part No | Quality of Machine | Part Name | Standard Material | Actual Material |

| 1 | 1 | Cylinder | Extruded aluminum alloy | Stainless steel |

| 2 | 1 | Output shaft | Carbon steel | Stainless steel |

| 3 | 1 | O-ring(at the bottom of the output shaft) | NBR | Fluorine/ silicon rubber |

| 4 | 1 | Bearing(at the bottom of the output shaft) | Nylon46 | – |

| 5 | 1 | Adjusting Cam | Stainless steel | – |

| 6 | 1 | Thrust Bearing(output shaft) | Nylon46 | – |

| 7 | 1 | Bearing(at the top of the output shaft) | Nylon46 | – |

| 8 | 1 | O-ring(at the top of the output shaft) | NBR | Fluorine/ silicon rubber |

| 9 | 1 | Bearing(at the top of the output shaft) | Nylon46 | – |

| 10 | 1 | Gasket((output shaft) | Stainless steel | – |

| 11 | 1 | Elastic damping ring | Stainless steel | – |

| 12 | 1 | Position indicator | PPPP+30%GF | – |

| 13 | 1 | Screw | PPPP+30%GF | – |

| 14 | 4 | Position indicator piece | PPPP+30%GF | – |

| 15 | 2 | Positon | Casting aluminum alloy | – |

| 16 | 2 | Guide bearing(at the back of piston) | Nylon46 | Fluorine/ silicon rubber |

| 17 | 2 | O-ring(piston) | NBR | – |

| 18 | 2 | Guide ring(piston) | Fluorine-carbon composite material | – |

| 19 | 5-12 | Spring assembly | Alloy spring steel | – |

| 20 | 2 | O-ring(end cap) | NBR | Fluorine/ silicon rubber |

| 21 | 1 | Left end cap | Casting aluminum alloy | Stainless steel |

| 22 | 1 | Right end cap | Casting aluminum alloy | Stainless steel |

| 23 | 8 | End cap bolt | Stainless steel | – |

| 24 | 2 | O-ring(adjusting bolt) | NBR | Fluorine/ silicon rubber |

| 25 | 2 | Gasket | Stainless steel | – |

| 26 | 2 | Nut | NBR | – |

| 27 | 2 | Adjusting bolt | Stainless steel |

Product Specifications

| Pressure Range: Max. Working pressure 10bar |

| Air pressure: 2.5bar~8bar |

| Adjustment Range: 90° ± 5° |

| Ambient temperature: -20 ~ +90° C |

| Type: Double acting, Single acting (spring return) |

| Optional accessories: Solenoid valve, limite switch, electric position, air regulator |

| Lubrication: All the moving parts are coated with lubricants, extending their service life |

| Life Time: One million time |

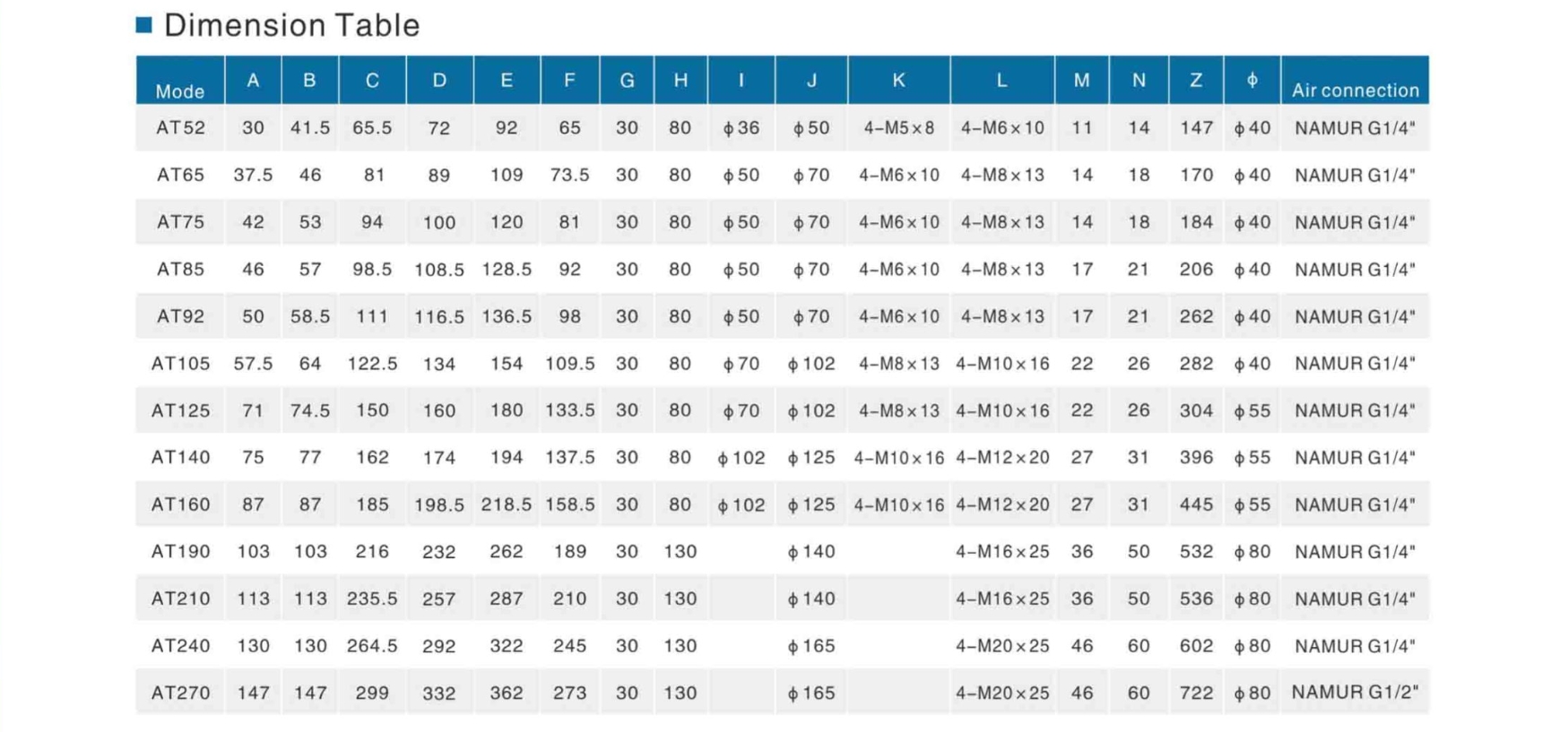

Dimension Of Pneumatic Actuator

Our Order Photos

Related products

-

Pneumatic Control Valve

YT1000 Rotary Electro Pneumatic Positioner

-

Pneumatic Control Valve

Double Square Adapter

-

Pneumatic Control Valve

YT1000 Linear ElectroPenumatic Positioner

-

Pneumatic Control Valve

Y-Type Pneumatic Angle Seat Piston Valve