304 Stainless Steel Pneumatic cylinder Piston Rod, Stainless Steel Shaft

Used as piston rod or guide rod for pneumatic cylinders. Use stainless steel 304, rod size from 3mm upto 90mm. Has high corrosion resistance, strength and wear resistance to keep high-efficiency operation

Piston Rod for Pneumatic Air Cylinder

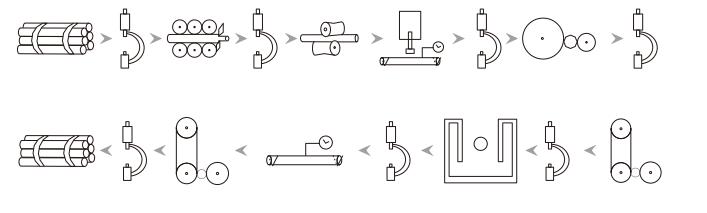

The rods first undergo precision milling and processing, and are then put through grind surface chromium treatment, allowing a surface precision level of f8, and a surface hardness reaching HV850 minimum and up, which not only help to improve wear resistance but also help to extend the life cycle of the rods, thus helping the customer save cost.

Application

Directly for cylinder, cylinder, shock absorber piston rod, and is widely used in textile printing and dyeing, printing machinery, guide rail, die-casting machine, injection molding machine guide rod, the ejector and other mechanical products of guide pin and four-column press guide post, fax machines, printers and other modern office machinery guide shaft and some precision slender shaft for the parts industry products.

Dimension:Φ 6~250mm

Tolerance: ISOf7/on request

Roundness:≤1/2 diameter tolerance

Standard length: <Φ 30mm, 2-3mts/on request cut length

≥Φ 30mm, 3-6mts/on request cut length

Surface Roughness: Ra≤0.2

Chrome layer thickness: Φ <20mm: min. 15um

Φ ≥20mm: min. 20um

Chrome layer hardness: HV850-HV1050

Straightness: 0.15/1000mm

Evaluation Corroseston Test: ISO10289:1999, IDT

Delivery condition: Normal, QT, Induction Hardened

Product Details

| specifications | φ6-φ12 | φ16-φ25 | φ30-φ50 | φ55-φ100 | φ105-φ1200 |

| length | 200-2000 | 200-3000 | 200-5000 | 200-10000 | 1000-10000 |

| Surface roughness | Ra<0.2 | ||||

| Surface Treatment of hardness | HRC6 | Straightness | 0.15/1000mm | ||

| Circle of Tolerance | GB1184 9 Grade | Chrome thickness | According to user requirements | ||

| Full-length size Tolerance | GB1100IT Grade | Material | According to user requirements | ||

| Axis of hardness | HB220-280 | ||||

| Availability Status | No surface treatment, chrome or nickel-phosphorus plating on the surface, salt spray nitriding on the surface | ||||

Steel grades correspondents

| GB | EN | DIN | B.S. | UNI | JIS | GOST | “AISISAEASTM” |

| 42CrMo | 42CrMo4 | 42CrMo4 | 708M40 | 42CrMo4 | SCM440(H) | 40ChFA | 4140 |

| 45# | C45E | CK45 | 080M46 | C45 | S45C | 45 | 1045 |

| 0Cr18Ni9 | X5CrNi18-10 | X5CrNi18-10 | 304S17 | X5CrNi18-10 | SUS304 | 08Ch18N10 | 304 |

| 2Cr13 | X20Cr13 | X20Cr13 | 420S37 | X20Cr13 | SUS420F | 20Ch13 | 420 |

| 1Cr17Ni2 | X17CrNi16-2 | X17CrNi16-2 | 431S29 | X16CrNi16 | SUS431 | 20Ch17N2 | 431 |

| 1Cr17 | X6Cr17 | X6Cr17 | 430S15 | X8Cr17 | SUS430 | – | 430 |

Chemmical composition-in % by weight

| “Steel grade” | C | SI | Mn | P | S | Cr | Mo | Ni |

| 42CrMo | 0.38~0.45 | 0.17~0.37 | 0.5~0.8 | ≤0.035 | ≤0.035 | 0.9~1.2 | 0.15~0.25 | ≤0.03 |

| 45# | 0.42~0.5 | 0.17~0.37 | 0.5~0.8 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.1 | ≤0.25 |

| 304 | ≤0.07 | ≤1 | ≤2 | ≤0.045 | ≤0.03 | 18-20 | – | 8-10.5 |

| 420 | 0.16-0.25 | ≤1 | ≤1.5 | ≤0.04 | ≤0.03 | 12-14 | – | 一 |

| 431 | 0.12-0.22 | ≤1 | ≤1.5 | ≤0.04 | ≤0.03 | 15-17 | – | 1.5-2.5 |

| 430 | ≤0.12 | ≤0.75 | ≤1 | ≤0.04 | ≤0.03 | 16-18 | – | ≤0.6 |

Mechanical properties

| Steel grade | Tensile N/mm² | Yield N/mm² | Elogation |

| 42CrMo+QT | ≥1080 | ≥930 | min.12% |

| 45#+QT | ≥600 | ≥390 | min.16% |

| 45# | ≥600 | ≥355 | min.16% |

| 304 | ≥520 | ≥205 | min.40% |

| 420 | ≥635 | ≥440 | min.20% |

| 431 | ≥800 | ≥600 | min.10% |

| 430 | ≥450 | ≥205 | min.22% |

Tolerance

| Diameter mm |

ISOf7 μm |

ISO f8 μm |

| φ=6 | -10/-22 | -10/-28 |

| 6<φ≤10 | -13/-28 | -13/-35 |

| 10<φ≤18 | -16/-34 | -16/-43 |

| 18<φ≤30 | -20/-41 | -20/-53 |

| 30<φ≤50 | -25/-50 | -25/-64 |

| 50<φ≤80 | -30/-60 | -30/-76 |

| 80<中≤120 | -36/-71 | -36/-90 |

| 120<φ≤180 | -43/-83 | -43/-106 |

| 180<φ≤250 | -50/-96 | -50/-122 |

Related products

-

Pneumatic Cylinder Kit

SDA compact cylinder kits

-

Pneumatic Cylinder Kit

SI ISO6431 standard cylinder kits

-

Pneumatic Cylinder Kit

PVC Vacuum Cap Round Rubber End Cap for Tube/Pipe/ Bolt, Screw Thread Protector

-

Pneumatic Cylinder Kit

Front Cover Back Cover of Pneumatic Cylinder