SMC Type MK/MK2/MK2T Rotary Clamp Pneumatics Cylinders

Mk Series Mk16 Mk20 Mk25 MK32 Mk40 Mk50 Mk63 Double Acting Rotary Clamp Pneumatic Air Cylinder

MK Series Port Thread Type Rotary Clamp Cylinder

Features

1).Normal bore size from 12mm to 63mm.

2).Provided with rubber cushion to make sure cylinder works smoothly,safely and with low noise.

3).Spray painted cylinder head and internal hard anodized cylinder body.

4).With self lubricating bearing,the piston rod is lubrication free.

5).Magnet and sufficient fixing style are available.

6).Precision grinding piston rod,cylinder parts were processed by high precision CNC machine and good seals to guarantee good action and long lifetime.

7).Different mounting ways are available for your selection.

Ordering Code

| MK | B | – | 20 | – | 10 | R |

| Series | Mounting Mode | Bore | Clamped Stroke | Back Rotation Direction | ||

| B:Through hole and screwing hole on both ends are used |

When pull back | |||||

| R:Clockwise | ||||||

| L:Counter clockwise |

Selection of sensor switch

| Inner diameter

Model |

12 | 16 | 20 | 25 | 32 | 40 | 50 |

| Sensor switch | D-A93 | D-A73 | |||||

Technical Specification

| Type | MK12 | MK16 | MK20 | MK25 | MK32 | MK40 | MK50 | MK63 |

| Bore Size(mm) | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 63 |

| Derived Model | MKB:Four Through Holes MKA:Four Holes with Thread L:Turn Left R:Turn Right |

|||||||

| Accessories Options | FB:Rear Flange | |||||||

| Acting Mode | Cleaned Air | |||||||

| Working Fluid | Double acting | |||||||

| Max.Working Pressure | 1Mpa | |||||||

| Min.Working Pressure | 0.1Mpa | |||||||

| Fluid Temperature | Magnetic switch: -10~+60℃; Non-magnetic switch: -10~+70℃ | |||||||

| Piston Speed | 50-200mm/s | |||||||

| Buffering | Rubber buffer | |||||||

| Stroke Tolerance(mm) | 0.2 | |||||||

| Lubrication | No need | |||||||

| Back-Rotation Angle | 90°±10° | |||||||

| Back-Rotation Direction | L/R | |||||||

| Back-Rotation Distance(mm) | 7.5 | 9.5 | 15 | 19 | ||||

| Clamping Distance(mm) | 10、20、30 | 10、20、30、50 | ||||||

| Allowed Bending Torque(N.m) | 1 | 3.8 | 7 | 13 | 27 | 47 | 107 | 182 |

| Clamping Force(N) | 40 | 75 | 100 | 185 | 300 | 525 | 825 | 1400 |

| Non-Rotation Accuracy Of Piston Rod | ±1.4° | ±1.2° | ±0.9° | ±0.7° | ||||

| Port Size | M5X0.8 | 1/8″ | 1/4″ | |||||

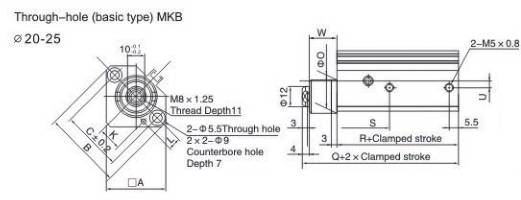

Dimension

|

Model |

A |

C |

D |

E |

F |

G |

H |

W |

|

MKB12 |

25 |

15.5 |

5 |

M3X0.5 |

5.5 |

11 |

6 |

9.5+Clamped stroke |

|

MKB16 |

29 |

20 |

7 |

M5X0.8 |

6.5 |

14 |

8 |

9.5+Clamped stroke |

|

Model |

A |

B |

C |

K |

L |

O |

Q |

R |

S |

U |

W |

|

MKB20 |

36 |

46.8 |

36 |

13.5±0.15 |

7.5 ± 0.15 |

20 0-0.52 |

72.5 |

62 |

31 |

4 |

6.5+Clamped stroke |

|

MKB25 |

40 |

52 |

40 |

16 ±0.15 |

8 ±0.15 |

23 0-0.52 |

73.5 |

63 |

32 |

5 |

6.5+Clamped stroke |

|

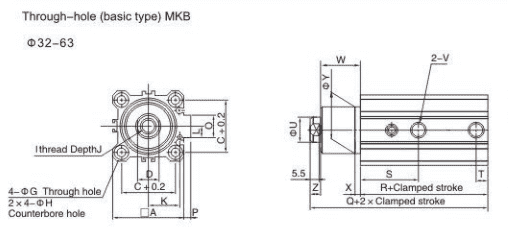

Model |

A |

C |

D |

G |

H |

I |

J |

K |

L |

|

MKB32 |

45 |

34 |

14 -0.1 -0.2 |

5.5 |

9 Depth7 |

M10X1.5 |

12 |

20 ±0.15 |

7 ±0.15 |

|

MKB40 |

52 |

40 |

14 -0.1 -0.2 |

5.5 |

9 Deplh7 |

M10X1.5 |

12 |

24 ±0.15 |

7 ±0.15 |

|

MKB50 |

64 |

50 |

17 -0.1 -0.2 |

6.6 |

11 Depth 9 |

M12X1.75 |

15 |

30 ±0.15 |

8 ±0.15 |

|

MKB63 |

77 |

60 |

17 -0.1 -0.2 |

9 |

14 Depth 10.5 |

M12X1.75 |

15 |

35 ±0.15 |

9 ±0.15 |

|

Model |

O |

P |

Q |

R |

S |

T |

U |

V |

X |

Y |

Z |

W |

|

MKB32 |

14 |

4.5 |

93.5 |

71.5 |

37 |

7.5 |

16 |

1/8 |

3 |

30 0-0. 62 |

6.5 |

15.5+Clamped stroke |

|

MKB40 |

14 |

5 |

94.5 |

65 |

29.5 |

8 |

16 |

1/8 |

3 |

30 0-0. 62 |

6.5 |

23.0+Clamped stroke |

|

MKB50 |

19 |

7 |

112 |

76.5 |

34 |

10.5 |

20 |

1/4 |

3.5 |

37 0-0. 62 |

7.5 |

28.0+Clamped stroke |

|

MKB63 |

19 |

7 |

115 |

80 |

35 |

10.5 |

20 |

1/4 |

3.5 |

48 0-0. 62 |

7.5 |

27.5+Clamped stroke |

|

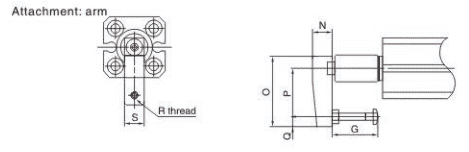

Model |

Bore |

N |

O |

P |

Q |

R |

S |

G |

|

MK-12-N |

12 |

8 |

29 |

20 |

4 |

M3x0.5 |

8 |

8-18 |

|

MK-16-N |

16 |

11 |

36 |

25 |

5 |

M4x0.7 |

11 |

8-18 |

|

MK-20/25-N |

20,25 |

14 |

51 |

35 |

7 |

M6x1.0 |

16 |

12-22 |

|

MK-32/40-N |

32,40 |

18 |

67 |

45 |

10 |

M8x1.25 |

20 |

15-25 |

|

MK-50/63-N |

50,63 |

22 |

88 |

65 |

10 |

M10X1.5 |

22 |

30-40 |

Related products

-

Pneumatic Cylinder

CJP Series Needle Cylinder

-

Pneumatic Cylinder

MSQ Series Rotary Table Rack & Pinion Cylinder

-

Pneumatic Cylinder

CU CDU Free Mount Pneumatic Cylinder

-

Pneumatic Cylinder

CXS(M) Series Double Rod Cylinder